Nowadays, with the rapid development of industrialization, air pollution is becoming more and more serious, which has a great impact on people’s health. With the continuous improvement of people’s living standards, people’s health awareness is constantly enhanced, which makes people pay more and more attention to the protection of oral cavity.

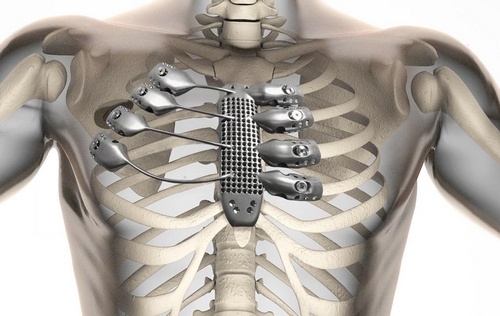

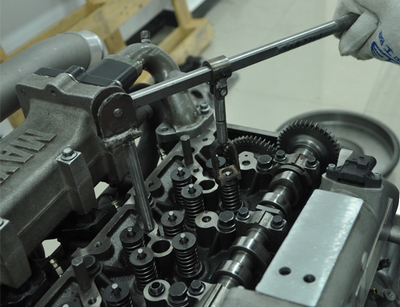

With the rapid development of modernization, the application requirements of materials in medical field are more and more stringent. Because titanium and titanium alloy materials have many fusions with human body, bone necrosis in surgery, dental implants, porcelain teeth and materials of many therapeutic instruments are required. Medical treatment should be based on titanium and titanium alloys. More and more. Because of its advantages, small proportion, close to the proportion of human bone, high strength and strong corrosion resistance, it is an ideal and safe medical material. Titanium and its titanium alloys have excellent properties, can contact with human body well, and do little harm to human body, even can be neglected. The density of titanium and its elastic modulus are very close to human bone, so its excellent properties make its clinical application very advantageous. Therefore, the use of pure titanium and its titanium alloy to make some medical equipment compatible with the human body, such as dental porcelain teeth, implants, dentures, dental beds, brackets, bridges, crowns, artificial joints, bone plates, bone screw and bone fixation needles, has been widely used in clinical: the use of pure titanium mesh made of skeletal brackets, through clinical practice The experiment has been used in the reconstruction of necrotic bones, the repair of damaged bones and dura mater with microporous titanium mesh can be used and the cerebrospinal fluid system can be effectively protected, and the artificial heart valves and cages made of pure titanium have been successfully applied with good clinical effect. Pure titanium is a silver-white metal with a silver-gray luster. It can be used as deoxidizer in steelmaking and as a component of stainless steel and alloy steel. Titanium powder can be used as raw materials for pigments and paints, as well as as as as electrodes and condensers for power plants and environmental pollution control devices. But the strength is low. Titanium alloys have high strength, such as Ti-6AI-4V, which is commonly used, and the strength of Ti-6AI-4V reaches the level of general high strength steel. Titanium alloy has higher heat resistance, low temperature toughness and fracture toughness than its titanium material, so it can be used for many industrial parts, such as aircraft engine parts, rocket and missile parts. In the petroleum industry, it is mainly used as various containers and reactors. Titanium-nickel shape memory alloy has been widely used in instruments. Titanium nitride is similar to gold in color and can be used as decorative material. Titanium and titanium alloys are widely used in aviation industry, which is called “space metal”. In addition, they are widely used in shipbuilding industry, chemical industry, manufacturing machinery parts, telecommunications equipment, cemented carbide and so on. In addition, titanium alloys can also be used as artificial bones, dentures, ceramic teeth and medical devices to fix various broken bones because of their good compatibility with the human body. Titanium alloys are widely used in dental field due to their light weight, strong corrosion resistance, high temperature resistance and good weldability. Titanium and titanium alloys are widely used as dental implants because of their good mechanical properties and biocompatibility. The neck of the implant is made of titanium and titanium alloy with smooth surface, so as to facilitate the wrapping of fibrous tissue, form a good epithelial cuff area and prevent plaque accumulation. The porous structure of the implant enlarges the surface area of the implant, provides conditions for the attachment and growth of bone tissue, and is conducive to the retention of the implant. The cell experiment results of the ZnHA/titanium dioxide biological coating prepared by the experiment showed that the osteoblasts adhered well to the ZnHA/titanium dioxide coating, the cell proliferation ability on the material surface was enhanced, and the better cell attachment inhibited the bacterial attachment on the implant surface to a certain extent. In recent years, implant surface treatment technology has developed rapidly, including X-ray jet, mechanical grinding, plasma sputtering, sandblasting or acid etching. The hardness of pure titanium and titanium alloys is increased by seven times and two times respectively by high temperature ion nitriding treatment on titanium surface. The annual corrosion rate of nitrided titanium is only one third of that of non-nitrided titanium, and it is non-toxic to the surrounding tissues. Titanium nitrided by biological tissues has a slight and non-toxic reaction. The oxide film formed on the surface of titanium and titanium alloys can be corroded by the most widely used dental caries preventive agent, preventive polishing and fluoride damage in oral cavity. This corrosion product can cause degeneration and necrosis of tissue cells, nonspecific inflammation, allergic reaction and even tumorigenesis. Corrosion of the alloy materials will affect the color and strength of the prosthesis and cause adverse biological reactions such as cytotoxicity and allergy. Titanium and titanium alloys are used as substitutes for hard tissues. It can be used as dental materials in mosaics, crowns, bridging materials, dental implants, artificial roots and so on. In recent ten years, with the development of science and technology, titanium and titanium alloys have a broader prospect as new dental restorative materials. At present, Au, Ni-Cr, Co-Cr, stainless steel and other alloys are mainly used to make denture scaffolds. The alloys have good biocompatibility, but the price is expensive and the color is not ideal. Other alloys contain harmful elements such as Ni, Co and Cr. As a new dental restorative material, titanium has good affinity with human skeletal epithelial tissue and connective tissue. Its mechanical properties can also be comparable with other dental alloys, and its density is small, and the denture is comfortable. Ti-6Al-4V alloy has superplasticity and is easy to make denture base. The results show that the maxillary palatal bracket made of pure titanium has good flexural resistance and biocompatibility. Titanium has gradually become a more and more important material in denture prosthesis, and it has become an economic and biocompatible substitute for removable and fixed denture alloys. It has no allergy to human tissues and is inexpensive. Titanium is a kind of metal element with light density, high strength, corrosion resistance, excellent performance and abundant reserves. It is a better dental material in terms of industrial value, resource life and development prospects. Titanium material has a series of characteristics, which are beneficial to human body and quite safe. It is very suitable for human body. Titanium materials have special current characteristics, which can produce beneficial physiological effects and chemical stability to human body. In the course of treatment, people’s mental state is relaxed and not tense, which will not cause medical accidents. The high hardness and light density of titanium make it not easy to rust and deteriorate, and its performance is stable in application. Therefore, dental high-speed mobile phones, dental optical fiber mobile phones, dental implants, in the process of work, dental mobile phones have to enter the human oral cavity, contact with human teeth more, so the choice of surface materials, mostly using titanium and its alloy materials to process, less harm to humanity, and its performance comparison Stable and reliable. This kind of light weight, high strength and special current characteristics can play a good role in human body. So titanium is widely used in medical, medical and sports fields. Titanium and titanium alloys have been used as biomaterials in human body due to their excellent biocompatibility and corrosion resistance. In particular, titanium materials as dental implants are widely used in the human body, and there are countless orthopaedic operations made of titanium materials. With the development of modern industry, the development of modern medical care and the progress of science and technology, the development of Stomatology has been very rapid. With the development of dental implantation, Titanium Precision casting, welding, bonding and ceramic technology, titanium has been widely used in various branches of Stomatology and has become a necessary medical material. Titanium and titanium alloys are relatively perfect industrial materials because of their excellent properties. However, due to their high hardness, there are some difficulties in cutting. Cutting titanium alloy should proceed from choosing reasonable cutting tools, reducing cutting temperature and reducing bonding. Cutting tools with good red hardness, high bending strength and good thermal conductivity, such as YG cemented carbide, are selected. They have high hardness and can be suitable for the processing of titanium and its alloy materials. After choosing the right tool, we should also pay attention to the grinding of the tool. In the process of processing, the grinding of the main parameters of the tool is still very important. For example, when should the front angle be grinded and what should be paid attention to at the rear angle? These are all very important links, generally for the processing of titanium and its alloy materials. They all have special people to sharpen tools. Moreover, when processing titanium and its alloy materials, we must also pay attention to reducing cutting temperature and choosing good coolant, because good coolant can reduce the number of tool replacement, penetrate into the cutting tool surface, improve surface finish, and greatly reduce the reject rate, so the choice of lubricant is also indispensable. And it is very important that with the appropriate cutting fluid, the material viscosity will be reduced in the process of processing, which is conducive to processing and can save time and effort. In summary, after understanding the properties of titanium and titanium alloys, we find that their advantages are great. As long as they have mastered its processing and selected the appropriate tool and coolant, there will be nothing to prevent its application. It is not difficult to see that titanium and titanium alloys not only in the field of oral cavity, but also in industry. It is very important to use it. As a modern metal, it has excellent performance.

The surface of pure titanium products has a dense oxide film, which can adapt to various environments well at room temperature. Therefore, without spraying, pure titanium kettles have strong corrosion resistance. Facing the weak acid or alkali environment outdoors, pure titanium kettles can handle freely, whether river water or rainwater, rocks or vegetation, pure titanium kettles can be directly contacted without being corroded. Because the whole body of the kettle is not painted, the kettle presents the unique gray of pure titanium products, and can be directly heated to dazzling color on the fire source. The colorful surface of titanium kettle is covered with a very thin layer of naturally formed oxide film (titanium and oxide titanium dioxide). This film can also become titanium rust, because its surface has formed a transparent film with high refractive index and the film plays a prism role, so that light refraction absorbs light of different wavelengths, and the color can be seen. Moreover, if the thickness of the oxide film is manually adjusted to 8-10 cm, according to the different wavelengths, it can appear. Thousands of similar colors. Because this film is a transparent film with high refractive index, it can show a variety of colors. For example, the pot cover is made of pure titanium and rubber. Considering the corrosion resistance and health of the product, the pure titanium pot cover has better properties. Pure titanium products are completely harmless to human body, so it is possible to heat water and food in pure titanium containers. Pure titanium kettle single layer does not have thermal insulation function, suitable for use below the snow line, with pure titanium kettle lid can be directly heated without tightening, so that the water quality has a better guarantee. Compared with the traditional stainless steel material, titanium density is smaller. The weight of 550 ml titanium kettle is only 99g. The quality of stainless steel kettle of the same specification is about twice that of pure titanium kettle. In the process of travel, lighter equipment often means higher efficiency. Applying pure titanium products to outdoor activities can reduce the burden of donkey friends. Pure titanium is of great strength, comparable to stainless steel and much better than lightweight aluminium products. In the process of climbing, collision is inevitable, even if the kettle falls on the stone, it is still intact. In some special cases, pure titanium kettles can even be used as support for emergencies.

The surface of pure titanium products has a dense oxide film, which can adapt to various environments well at room temperature. Therefore, without spraying, pure titanium kettles have strong corrosion resistance. Facing the weak acid or alkali environment outdoors, pure titanium kettles can handle freely, whether river water or rainwater, rocks or vegetation, pure titanium kettles can be directly contacted without being corroded. Because the whole body of the kettle is not painted, the kettle presents the unique gray of pure titanium products, and can be directly heated to dazzling color on the fire source. The colorful surface of titanium kettle is covered with a very thin layer of naturally formed oxide film (titanium and oxide titanium dioxide). This film can also become titanium rust, because its surface has formed a transparent film with high refractive index and the film plays a prism role, so that light refraction absorbs light of different wavelengths, and the color can be seen. Moreover, if the thickness of the oxide film is manually adjusted to 8-10 cm, according to the different wavelengths, it can appear. Thousands of similar colors. Because this film is a transparent film with high refractive index, it can show a variety of colors. For example, the pot cover is made of pure titanium and rubber. Considering the corrosion resistance and health of the product, the pure titanium pot cover has better properties. Pure titanium products are completely harmless to human body, so it is possible to heat water and food in pure titanium containers. Pure titanium kettle single layer does not have thermal insulation function, suitable for use below the snow line, with pure titanium kettle lid can be directly heated without tightening, so that the water quality has a better guarantee. Compared with the traditional stainless steel material, titanium density is smaller. The weight of 550 ml titanium kettle is only 99g. The quality of stainless steel kettle of the same specification is about twice that of pure titanium kettle. In the process of travel, lighter equipment often means higher efficiency. Applying pure titanium products to outdoor activities can reduce the burden of donkey friends. Pure titanium is of great strength, comparable to stainless steel and much better than lightweight aluminium products. In the process of climbing, collision is inevitable, even if the kettle falls on the stone, it is still intact. In some special cases, pure titanium kettles can even be used as support for emergencies. The outstanding advantage of titanium alloy is its high strength, but its weight is much lighter than that of ordinary metals. It is a very ideal bullet-proof material. However, the processing technology of titanium alloys is very complex, resulting in its very expensive cost. There are few real ballistic materials of titanium alloys produced in the world. However, the former Soviet Union is an exception. They have abundant raw materials of titanium metal in China. The processing technology of titanium alloy has always been in the leading position in the world. The titanium alloy bomber and the titanium alloy submarine they developed are the performance monsters of that era. So it is not difficult to understand why only the Soviet Union developed and equipped a large number of titanium alloy helmet. The history of the Soviet Union equipped with titanium alloy helmet can be traced back to the middle and late 1980s. At that time, the Soviet Special Forces in Afghanistan began to equip STSh-81 titanium alloy helmet, which weighed 2.4 kg and consisted of three titanium alloy bullet-proof plates with a thicker inner liner to reduce impact. The improved version is STSh-94, which is quite common in photographs, including the hostage incident in Beslan and other operations, you can see the use of this helmet. The Soviet Union has also been equipped with a 6B6 heavy titanium alloy helmet, which looks very strange, like a mask worn by welders, weighing up to 3.5 kilograms. Because of its heavy weight, it is usually used in anti-terrorism operations and is not suitable for the field environment. The helmet is made of spherical body, with an integral face mask that can be turned up in front and an observation slit. The helmet can meet the protection standard of-_-5, that is, the highest level of protection required by the Russian Federal Ministry of Internal Affairs. Because of the high price, these titanium alloy helmet was only equipped with the most elite special forces of the Soviet Union at that time, and can be seen in the war in Afghanistan, Chechnya and all previous anti-terrorism operations. The bullet-proof capability of titanium alloy helmet is absolutely unknown. It can not only deal with all kinds of fragments easily, but also resist the shooting of 5.45 mm and 7.62 mm ordinary projectiles at a long distance, which is incomparable with modern Kevlar materials. But the titanium alloy helmet also has a big problem. After all, the weight of two or three kilograms, if worn for a long time, will still affect the combat effectiveness of soldiers. Therefore, since entering the new century, it has gradually been replaced by Kevlar helmet. However, the bullet-proof ability of titanium alloy is very attractive. With the continuous development of titanium alloy materials and processing technology, there may be a large number of titanium alloy helmet with excellent performance and low cost in the future.

The outstanding advantage of titanium alloy is its high strength, but its weight is much lighter than that of ordinary metals. It is a very ideal bullet-proof material. However, the processing technology of titanium alloys is very complex, resulting in its very expensive cost. There are few real ballistic materials of titanium alloys produced in the world. However, the former Soviet Union is an exception. They have abundant raw materials of titanium metal in China. The processing technology of titanium alloy has always been in the leading position in the world. The titanium alloy bomber and the titanium alloy submarine they developed are the performance monsters of that era. So it is not difficult to understand why only the Soviet Union developed and equipped a large number of titanium alloy helmet. The history of the Soviet Union equipped with titanium alloy helmet can be traced back to the middle and late 1980s. At that time, the Soviet Special Forces in Afghanistan began to equip STSh-81 titanium alloy helmet, which weighed 2.4 kg and consisted of three titanium alloy bullet-proof plates with a thicker inner liner to reduce impact. The improved version is STSh-94, which is quite common in photographs, including the hostage incident in Beslan and other operations, you can see the use of this helmet. The Soviet Union has also been equipped with a 6B6 heavy titanium alloy helmet, which looks very strange, like a mask worn by welders, weighing up to 3.5 kilograms. Because of its heavy weight, it is usually used in anti-terrorism operations and is not suitable for the field environment. The helmet is made of spherical body, with an integral face mask that can be turned up in front and an observation slit. The helmet can meet the protection standard of-_-5, that is, the highest level of protection required by the Russian Federal Ministry of Internal Affairs. Because of the high price, these titanium alloy helmet was only equipped with the most elite special forces of the Soviet Union at that time, and can be seen in the war in Afghanistan, Chechnya and all previous anti-terrorism operations. The bullet-proof capability of titanium alloy helmet is absolutely unknown. It can not only deal with all kinds of fragments easily, but also resist the shooting of 5.45 mm and 7.62 mm ordinary projectiles at a long distance, which is incomparable with modern Kevlar materials. But the titanium alloy helmet also has a big problem. After all, the weight of two or three kilograms, if worn for a long time, will still affect the combat effectiveness of soldiers. Therefore, since entering the new century, it has gradually been replaced by Kevlar helmet. However, the bullet-proof ability of titanium alloy is very attractive. With the continuous development of titanium alloy materials and processing technology, there may be a large number of titanium alloy helmet with excellent performance and low cost in the future. With the rapid development of modernization, the application requirements of materials in medical field are more and more stringent. Because titanium and titanium alloy materials have many fusions with human body, bone necrosis in surgery, dental implants, porcelain teeth and materials of many therapeutic instruments are required. Medical treatment should be based on titanium and titanium alloys. More and more. Because of its advantages, small proportion, close to the proportion of human bone, high strength and strong corrosion resistance, it is an ideal and safe medical material. Titanium and its titanium alloys have excellent properties, can contact with human body well, and do little harm to human body, even can be neglected. The density of titanium and its elastic modulus are very close to human bone, so its excellent properties make its clinical application very advantageous. Therefore, the use of pure titanium and its titanium alloy to make some medical equipment compatible with the human body, such as dental porcelain teeth, implants, dentures, dental beds, brackets, bridges, crowns, artificial joints, bone plates, bone screw and bone fixation needles, has been widely used in clinical: the use of pure titanium mesh made of skeletal brackets, through clinical practice The experiment has been used in the reconstruction of necrotic bones, the repair of damaged bones and dura mater with microporous titanium mesh can be used and the cerebrospinal fluid system can be effectively protected, and the artificial heart valves and cages made of pure titanium have been successfully applied with good clinical effect. Pure titanium is a silver-white metal with a silver-gray luster. It can be used as deoxidizer in steelmaking and as a component of stainless steel and alloy steel. Titanium powder can be used as raw materials for pigments and paints, as well as as as as electrodes and condensers for power plants and environmental pollution control devices. But the strength is low. Titanium alloys have high strength, such as Ti-6AI-4V, which is commonly used, and the strength of Ti-6AI-4V reaches the level of general high strength steel. Titanium alloy has higher heat resistance, low temperature toughness and fracture toughness than its titanium material, so it can be used for many industrial parts, such as aircraft engine parts, rocket and missile parts. In the petroleum industry, it is mainly used as various containers and reactors. Titanium-nickel shape memory alloy has been widely used in instruments. Titanium nitride is similar to gold in color and can be used as decorative material. Titanium and titanium alloys are widely used in aviation industry, which is called “space metal”. In addition, they are widely used in shipbuilding industry, chemical industry, manufacturing machinery parts, telecommunications equipment, cemented carbide and so on. In addition, titanium alloys can also be used as artificial bones, dentures, ceramic teeth and medical devices to fix various broken bones because of their good compatibility with the human body. Titanium alloys are widely used in dental field due to their light weight, strong corrosion resistance, high temperature resistance and good weldability. Titanium and titanium alloys are widely used as dental implants because of their good mechanical properties and biocompatibility. The neck of the implant is made of titanium and titanium alloy with smooth surface, so as to facilitate the wrapping of fibrous tissue, form a good epithelial cuff area and prevent plaque accumulation. The porous structure of the implant enlarges the surface area of the implant, provides conditions for the attachment and growth of bone tissue, and is conducive to the retention of the implant. The cell experiment results of the ZnHA/titanium dioxide biological coating prepared by the experiment showed that the osteoblasts adhered well to the ZnHA/titanium dioxide coating, the cell proliferation ability on the material surface was enhanced, and the better cell attachment inhibited the bacterial attachment on the implant surface to a certain extent. In recent years, implant surface treatment technology has developed rapidly, including X-ray jet, mechanical grinding, plasma sputtering, sandblasting or acid etching. The hardness of pure titanium and titanium alloys is increased by seven times and two times respectively by high temperature ion nitriding treatment on titanium surface. The annual corrosion rate of nitrided titanium is only one third of that of non-nitrided titanium, and it is non-toxic to the surrounding tissues. Titanium nitrided by biological tissues has a slight and non-toxic reaction. The oxide film formed on the surface of titanium and titanium alloys can be corroded by the most widely used dental caries preventive agent, preventive polishing and fluoride damage in oral cavity. This corrosion product can cause degeneration and necrosis of tissue cells, nonspecific inflammation, allergic reaction and even tumorigenesis. Corrosion of the alloy materials will affect the color and strength of the prosthesis and cause adverse biological reactions such as cytotoxicity and allergy. Titanium and titanium alloys are used as substitutes for hard tissues. It can be used as dental materials in mosaics, crowns, bridging materials, dental implants, artificial roots and so on. In recent ten years, with the development of science and technology, titanium and titanium alloys have a broader prospect as new dental restorative materials. At present, Au, Ni-Cr, Co-Cr, stainless steel and other alloys are mainly used to make denture scaffolds. The alloys have good biocompatibility, but the price is expensive and the color is not ideal. Other alloys contain harmful elements such as Ni, Co and Cr. As a new dental restorative material, titanium has good affinity with human skeletal epithelial tissue and connective tissue. Its mechanical properties can also be comparable with other dental alloys, and its density is small, and the denture is comfortable. Ti-6Al-4V alloy has superplasticity and is easy to make denture base. The results show that the maxillary palatal bracket made of pure titanium has good flexural resistance and biocompatibility. Titanium has gradually become a more and more important material in denture prosthesis, and it has become an economic and biocompatible substitute for removable and fixed denture alloys. It has no allergy to human tissues and is inexpensive. Titanium is a kind of metal element with light density, high strength, corrosion resistance, excellent performance and abundant reserves. It is a better dental material in terms of industrial value, resource life and development prospects. Titanium material has a series of characteristics, which are beneficial to human body and quite safe. It is very suitable for human body. Titanium materials have special current characteristics, which can produce beneficial physiological effects and chemical stability to human body. In the course of treatment, people’s mental state is relaxed and not tense, which will not cause medical accidents. The high hardness and light density of titanium make it not easy to rust and deteriorate, and its performance is stable in application. Therefore, dental high-speed mobile phones, dental optical fiber mobile phones, dental implants, in the process of work, dental mobile phones have to enter the human oral cavity, contact with human teeth more, so the choice of surface materials, mostly using titanium and its alloy materials to process, less harm to humanity, and its performance comparison Stable and reliable. This kind of light weight, high strength and special current characteristics can play a good role in human body. So titanium is widely used in medical, medical and sports fields. Titanium and titanium alloys have been used as biomaterials in human body due to their excellent biocompatibility and corrosion resistance. In particular, titanium materials as dental implants are widely used in the human body, and there are countless orthopaedic operations made of titanium materials. With the development of modern industry, the development of modern medical care and the progress of science and technology, the development of Stomatology has been very rapid. With the development of dental implantation, Titanium Precision casting, welding, bonding and ceramic technology, titanium has been widely used in various branches of Stomatology and has become a necessary medical material. Titanium and titanium alloys are relatively perfect industrial materials because of their excellent properties. However, due to their high hardness, there are some difficulties in cutting. Cutting titanium alloy should proceed from choosing reasonable cutting tools, reducing cutting temperature and reducing bonding. Cutting tools with good red hardness, high bending strength and good thermal conductivity, such as YG cemented carbide, are selected. They have high hardness and can be suitable for the processing of titanium and its alloy materials. After choosing the right tool, we should also pay attention to the grinding of the tool. In the process of processing, the grinding of the main parameters of the tool is still very important. For example, when should the front angle be grinded and what should be paid attention to at the rear angle? These are all very important links, generally for the processing of titanium and its alloy materials. They all have special people to sharpen tools. Moreover, when processing titanium and its alloy materials, we must also pay attention to reducing cutting temperature and choosing good coolant, because good coolant can reduce the number of tool replacement, penetrate into the cutting tool surface, improve surface finish, and greatly reduce the reject rate, so the choice of lubricant is also indispensable. And it is very important that with the appropriate cutting fluid, the material viscosity will be reduced in the process of processing, which is conducive to processing and can save time and effort. In summary, after understanding the properties of titanium and titanium alloys, we find that their advantages are great. As long as they have mastered its processing and selected the appropriate tool and coolant, there will be nothing to prevent its application. It is not difficult to see that titanium and titanium alloys not only in the field of oral cavity, but also in industry. It is very important to use it. As a modern metal, it has excellent performance.

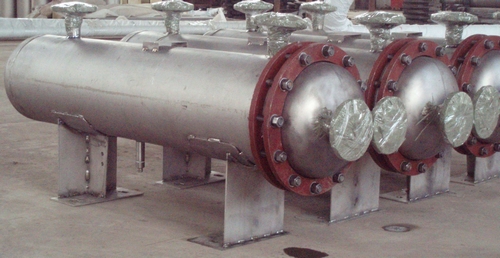

With the rapid development of modernization, the application requirements of materials in medical field are more and more stringent. Because titanium and titanium alloy materials have many fusions with human body, bone necrosis in surgery, dental implants, porcelain teeth and materials of many therapeutic instruments are required. Medical treatment should be based on titanium and titanium alloys. More and more. Because of its advantages, small proportion, close to the proportion of human bone, high strength and strong corrosion resistance, it is an ideal and safe medical material. Titanium and its titanium alloys have excellent properties, can contact with human body well, and do little harm to human body, even can be neglected. The density of titanium and its elastic modulus are very close to human bone, so its excellent properties make its clinical application very advantageous. Therefore, the use of pure titanium and its titanium alloy to make some medical equipment compatible with the human body, such as dental porcelain teeth, implants, dentures, dental beds, brackets, bridges, crowns, artificial joints, bone plates, bone screw and bone fixation needles, has been widely used in clinical: the use of pure titanium mesh made of skeletal brackets, through clinical practice The experiment has been used in the reconstruction of necrotic bones, the repair of damaged bones and dura mater with microporous titanium mesh can be used and the cerebrospinal fluid system can be effectively protected, and the artificial heart valves and cages made of pure titanium have been successfully applied with good clinical effect. Pure titanium is a silver-white metal with a silver-gray luster. It can be used as deoxidizer in steelmaking and as a component of stainless steel and alloy steel. Titanium powder can be used as raw materials for pigments and paints, as well as as as as electrodes and condensers for power plants and environmental pollution control devices. But the strength is low. Titanium alloys have high strength, such as Ti-6AI-4V, which is commonly used, and the strength of Ti-6AI-4V reaches the level of general high strength steel. Titanium alloy has higher heat resistance, low temperature toughness and fracture toughness than its titanium material, so it can be used for many industrial parts, such as aircraft engine parts, rocket and missile parts. In the petroleum industry, it is mainly used as various containers and reactors. Titanium-nickel shape memory alloy has been widely used in instruments. Titanium nitride is similar to gold in color and can be used as decorative material. Titanium and titanium alloys are widely used in aviation industry, which is called “space metal”. In addition, they are widely used in shipbuilding industry, chemical industry, manufacturing machinery parts, telecommunications equipment, cemented carbide and so on. In addition, titanium alloys can also be used as artificial bones, dentures, ceramic teeth and medical devices to fix various broken bones because of their good compatibility with the human body. Titanium alloys are widely used in dental field due to their light weight, strong corrosion resistance, high temperature resistance and good weldability. Titanium and titanium alloys are widely used as dental implants because of their good mechanical properties and biocompatibility. The neck of the implant is made of titanium and titanium alloy with smooth surface, so as to facilitate the wrapping of fibrous tissue, form a good epithelial cuff area and prevent plaque accumulation. The porous structure of the implant enlarges the surface area of the implant, provides conditions for the attachment and growth of bone tissue, and is conducive to the retention of the implant. The cell experiment results of the ZnHA/titanium dioxide biological coating prepared by the experiment showed that the osteoblasts adhered well to the ZnHA/titanium dioxide coating, the cell proliferation ability on the material surface was enhanced, and the better cell attachment inhibited the bacterial attachment on the implant surface to a certain extent. In recent years, implant surface treatment technology has developed rapidly, including X-ray jet, mechanical grinding, plasma sputtering, sandblasting or acid etching. The hardness of pure titanium and titanium alloys is increased by seven times and two times respectively by high temperature ion nitriding treatment on titanium surface. The annual corrosion rate of nitrided titanium is only one third of that of non-nitrided titanium, and it is non-toxic to the surrounding tissues. Titanium nitrided by biological tissues has a slight and non-toxic reaction. The oxide film formed on the surface of titanium and titanium alloys can be corroded by the most widely used dental caries preventive agent, preventive polishing and fluoride damage in oral cavity. This corrosion product can cause degeneration and necrosis of tissue cells, nonspecific inflammation, allergic reaction and even tumorigenesis. Corrosion of the alloy materials will affect the color and strength of the prosthesis and cause adverse biological reactions such as cytotoxicity and allergy. Titanium and titanium alloys are used as substitutes for hard tissues. It can be used as dental materials in mosaics, crowns, bridging materials, dental implants, artificial roots and so on. In recent ten years, with the development of science and technology, titanium and titanium alloys have a broader prospect as new dental restorative materials. At present, Au, Ni-Cr, Co-Cr, stainless steel and other alloys are mainly used to make denture scaffolds. The alloys have good biocompatibility, but the price is expensive and the color is not ideal. Other alloys contain harmful elements such as Ni, Co and Cr. As a new dental restorative material, titanium has good affinity with human skeletal epithelial tissue and connective tissue. Its mechanical properties can also be comparable with other dental alloys, and its density is small, and the denture is comfortable. Ti-6Al-4V alloy has superplasticity and is easy to make denture base. The results show that the maxillary palatal bracket made of pure titanium has good flexural resistance and biocompatibility. Titanium has gradually become a more and more important material in denture prosthesis, and it has become an economic and biocompatible substitute for removable and fixed denture alloys. It has no allergy to human tissues and is inexpensive. Titanium is a kind of metal element with light density, high strength, corrosion resistance, excellent performance and abundant reserves. It is a better dental material in terms of industrial value, resource life and development prospects. Titanium material has a series of characteristics, which are beneficial to human body and quite safe. It is very suitable for human body. Titanium materials have special current characteristics, which can produce beneficial physiological effects and chemical stability to human body. In the course of treatment, people’s mental state is relaxed and not tense, which will not cause medical accidents. The high hardness and light density of titanium make it not easy to rust and deteriorate, and its performance is stable in application. Therefore, dental high-speed mobile phones, dental optical fiber mobile phones, dental implants, in the process of work, dental mobile phones have to enter the human oral cavity, contact with human teeth more, so the choice of surface materials, mostly using titanium and its alloy materials to process, less harm to humanity, and its performance comparison Stable and reliable. This kind of light weight, high strength and special current characteristics can play a good role in human body. So titanium is widely used in medical, medical and sports fields. Titanium and titanium alloys have been used as biomaterials in human body due to their excellent biocompatibility and corrosion resistance. In particular, titanium materials as dental implants are widely used in the human body, and there are countless orthopaedic operations made of titanium materials. With the development of modern industry, the development of modern medical care and the progress of science and technology, the development of Stomatology has been very rapid. With the development of dental implantation, Titanium Precision casting, welding, bonding and ceramic technology, titanium has been widely used in various branches of Stomatology and has become a necessary medical material. Titanium and titanium alloys are relatively perfect industrial materials because of their excellent properties. However, due to their high hardness, there are some difficulties in cutting. Cutting titanium alloy should proceed from choosing reasonable cutting tools, reducing cutting temperature and reducing bonding. Cutting tools with good red hardness, high bending strength and good thermal conductivity, such as YG cemented carbide, are selected. They have high hardness and can be suitable for the processing of titanium and its alloy materials. After choosing the right tool, we should also pay attention to the grinding of the tool. In the process of processing, the grinding of the main parameters of the tool is still very important. For example, when should the front angle be grinded and what should be paid attention to at the rear angle? These are all very important links, generally for the processing of titanium and its alloy materials. They all have special people to sharpen tools. Moreover, when processing titanium and its alloy materials, we must also pay attention to reducing cutting temperature and choosing good coolant, because good coolant can reduce the number of tool replacement, penetrate into the cutting tool surface, improve surface finish, and greatly reduce the reject rate, so the choice of lubricant is also indispensable. And it is very important that with the appropriate cutting fluid, the material viscosity will be reduced in the process of processing, which is conducive to processing and can save time and effort. In summary, after understanding the properties of titanium and titanium alloys, we find that their advantages are great. As long as they have mastered its processing and selected the appropriate tool and coolant, there will be nothing to prevent its application. It is not difficult to see that titanium and titanium alloys not only in the field of oral cavity, but also in industry. It is very important to use it. As a modern metal, it has excellent performance. Some petrochemical enterprises and petroleum processing industries have experience in manufacturing and using titanium alloy equipment. For example, Moscow Petroleum Processing Plant manufactures the following equipment from BT1-0 titanium alloy: propylene polymerization reactor, decomposer decomposer pulsator, condenser, scrubbing tower. Titanium-lined containers can be used for evaporation (concentration) or distillation, or for reactions in weak acids or other chloride-containing solutions. Titanium-lined containers can also be used for nitriding organic materials with nitric acid and chemical reactions with other oxidizing media. Solution containing chromic acid and chromic acid solution vulcanizing can be selected according to the reaction temperature needs of this container with titanium lining. It has been proved that copper and other solutions containing gases can be used as catalysts for the catalytic oxidation of carbon chloride compounds when the pH value is determined. Then, when catalysis is carried out at about 150-200 t: temperature, the corresponding equipment must be set up, and acetaldehyde production equipment made of titanium is widely used. Towers, pipes, valves lined with titanium and acid pumps composed of rotors and stators are all made of Engineering pure titanium. Distillation column is often used for acetic acid purification, and most of the components included in the fractionation stage are made of titanium. For example, the middle layer and connecting parts of tower for distillation unit. Serpentine tube heater, which can prevent the formation of metal sulfate, after testing, compared with copper serpentine tube heater plated with aluminum, heat conduction increased by 30%. For urea reactor, in order to obtain (recover) carbon black and eliminate stress, a reactor with a diameter of 43M and a length of 8.2m withstanding 120T: temperature and 130kPa pressure is used. The reactor is designed to reduce the pressure of gas and other gases. This equipment is made of titanium. The application of titanium is further extended to crude oil and petroleum processing industry. The desalination equipment for producing fresh water or drinking water from seawater or organic acid are all made of titanium. At the same time, pumps, tubes and heat exchangers made of welded titanium tubes are reliable and durable through practice. Titanium seed plate for cathode is made of titanium plate in copper electrolysis.

Some petrochemical enterprises and petroleum processing industries have experience in manufacturing and using titanium alloy equipment. For example, Moscow Petroleum Processing Plant manufactures the following equipment from BT1-0 titanium alloy: propylene polymerization reactor, decomposer decomposer pulsator, condenser, scrubbing tower. Titanium-lined containers can be used for evaporation (concentration) or distillation, or for reactions in weak acids or other chloride-containing solutions. Titanium-lined containers can also be used for nitriding organic materials with nitric acid and chemical reactions with other oxidizing media. Solution containing chromic acid and chromic acid solution vulcanizing can be selected according to the reaction temperature needs of this container with titanium lining. It has been proved that copper and other solutions containing gases can be used as catalysts for the catalytic oxidation of carbon chloride compounds when the pH value is determined. Then, when catalysis is carried out at about 150-200 t: temperature, the corresponding equipment must be set up, and acetaldehyde production equipment made of titanium is widely used. Towers, pipes, valves lined with titanium and acid pumps composed of rotors and stators are all made of Engineering pure titanium. Distillation column is often used for acetic acid purification, and most of the components included in the fractionation stage are made of titanium. For example, the middle layer and connecting parts of tower for distillation unit. Serpentine tube heater, which can prevent the formation of metal sulfate, after testing, compared with copper serpentine tube heater plated with aluminum, heat conduction increased by 30%. For urea reactor, in order to obtain (recover) carbon black and eliminate stress, a reactor with a diameter of 43M and a length of 8.2m withstanding 120T: temperature and 130kPa pressure is used. The reactor is designed to reduce the pressure of gas and other gases. This equipment is made of titanium. The application of titanium is further extended to crude oil and petroleum processing industry. The desalination equipment for producing fresh water or drinking water from seawater or organic acid are all made of titanium. At the same time, pumps, tubes and heat exchangers made of welded titanium tubes are reliable and durable through practice. Titanium seed plate for cathode is made of titanium plate in copper electrolysis. In 1990, martensite activated nickel-titanium alloy: TTR is lower than or very close to the oral temperature, and exists in a multivariate state at room temperature, which is easy to deform. When placed in the oral cavity, martensite caused by stress and room temperature simultaneously transforms to austenite, i.e. shape memory function and superelasticity exist. It is easy to deform at room temperature (about 25 C) and below, but when it reaches a certain temperature (about 32 C), it will return to the original preform, showing the characteristics of shape memory and superelasticity. The Smart Brand of Beijing Saint Matt Technology Co., Ltd. and NitinolHA Brand of 3M Company are typical representative products. Thermally activated nickel-titanium archwire can be easily shaped and placed in the bracket because of this characteristic. When activated by the temperature and heat of the receptor in the oral cavity, it can produce shape restoring force and provide the required strength for orthopedics. Because the thermally activated nickel-titanium orthodontic wire has the characteristics of “softening in cold and becoming elastic in heat activation”, patients can change the orthodontic force by means of cold and hot water in mouth under the guidance of doctors, which is more convenient for Orthodontists and reduces the discomfort of initial orthodontic treatment. Increased thermodynamic nickel-titanium alloy: TTR temperature is higher than oral temperature, about 40 degrees Celsius, so that when the nickel-titanium archwire is placed in the mouth, it is still in a pluralistic state, the archwire is relatively soft, and austenite transformation occurs only when the mouth contains hot water. Therefore, the orthodontic force is weaker and can be used as the initial arch wire for adult patients and periodontal patients. The copper-nickel-titanium wire produced by Omcro and the Japanese low-lag L-H nickel-titanium arch wire have this property. Clinical application of Ti-Ni alloy wire:

In 1990, martensite activated nickel-titanium alloy: TTR is lower than or very close to the oral temperature, and exists in a multivariate state at room temperature, which is easy to deform. When placed in the oral cavity, martensite caused by stress and room temperature simultaneously transforms to austenite, i.e. shape memory function and superelasticity exist. It is easy to deform at room temperature (about 25 C) and below, but when it reaches a certain temperature (about 32 C), it will return to the original preform, showing the characteristics of shape memory and superelasticity. The Smart Brand of Beijing Saint Matt Technology Co., Ltd. and NitinolHA Brand of 3M Company are typical representative products. Thermally activated nickel-titanium archwire can be easily shaped and placed in the bracket because of this characteristic. When activated by the temperature and heat of the receptor in the oral cavity, it can produce shape restoring force and provide the required strength for orthopedics. Because the thermally activated nickel-titanium orthodontic wire has the characteristics of “softening in cold and becoming elastic in heat activation”, patients can change the orthodontic force by means of cold and hot water in mouth under the guidance of doctors, which is more convenient for Orthodontists and reduces the discomfort of initial orthodontic treatment. Increased thermodynamic nickel-titanium alloy: TTR temperature is higher than oral temperature, about 40 degrees Celsius, so that when the nickel-titanium archwire is placed in the mouth, it is still in a pluralistic state, the archwire is relatively soft, and austenite transformation occurs only when the mouth contains hot water. Therefore, the orthodontic force is weaker and can be used as the initial arch wire for adult patients and periodontal patients. The copper-nickel-titanium wire produced by Omcro and the Japanese low-lag L-H nickel-titanium arch wire have this property. Clinical application of Ti-Ni alloy wire: