Titanium Springs VS SLS Springs

What is SLS springs

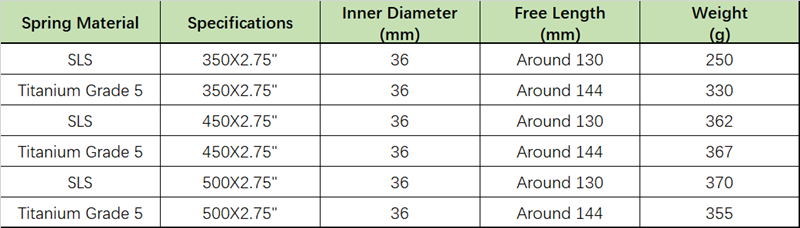

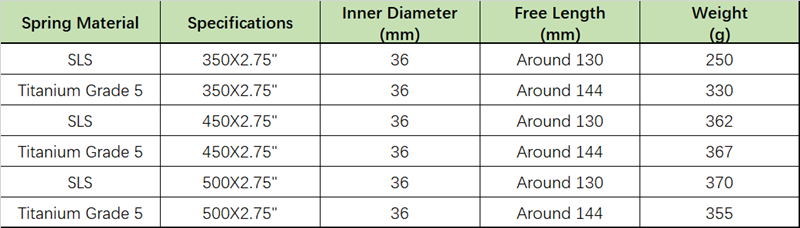

SLS is also called Super Light Springs,it is made from Super Alloy Steels.Compared with Normal Steel springs,it can designed with smaller volume and much lower weight just like titanium springs.And compared with titanium springs,some SLS springs has lower weight than the normal titanium springs,but some SLS springs weight is higher.For example as below chart.

We can see that the 350×2.75″ SLS spring has much lower weight than titanium Grade 5 springs;the weight of the 450×2.75″ SLS spring is even the same as the titanium spring;the titanium 500×2.75″ spring has even 15g lower weight than SLS springs.So not all SLS springs will has lower weight than titanium Grade 5 springs.

So anybody who want rearshock springs for your bicycles,you can compare the weight of the titanium springs and SLS springs at first.

I read an artical from Pinkbike.com,the SLS spring sold at 130USD/piece. And many other titanium springs are sold with very high prices.

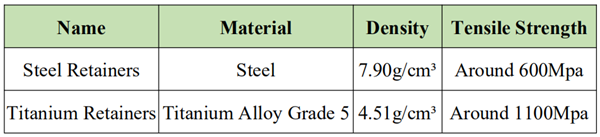

For us,we keep reserching and producing titanium springs for around 10 years,we also produce titanium springs for our customers,we sell our titanium springs at much lower prices and high quality. Our titanium Grade 5 spring has much lower price than the SLS springs.Titanium springs also has below advantages which SLS springs can’t compare.

1. Titanium Springs can be anodized to many colors including Gold,Blue,Purple,Green,Rainbow colors. And they can be PVD coated to Black,Oilslick and Burnt colors.

2. Titanium has excellent corrosion resistance features and it won’t get rusty.But SLS springs usually have to be plastic coated or Painted to avoid its finish get rusty.

Spring rates of titanium springs

Also people think that titanium springs don’t has accurate spring rates as it demanded.Our answer is no.The spring rates has tolerances,but tolerances is small.The spring rates tolerances comes from tolerances of spring sizes including wire diameter,inner diameter and numbers of coils.For us,we has many years experiences on titanium spring designing and production,we know how to control the accuracy of the titanium springs.And all springs will be tested before shipping to customers.

Beta-C titanium springs

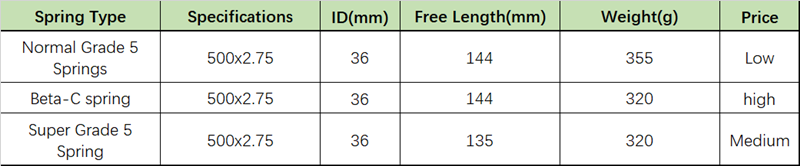

Except Grade 5 titanium springs,we also produce Beta-C springs.The Beta-C material has much more excellent features than Grade 5 material,after Solution & Aging heat treatment,its tensile strength even can reach to more than 1300Mpa.It can be designed with smaller wire diameter and less coils,its weight will be more lighter than Grade 5 springs.But its cost is very high.Below are the reasons why Beta-C spring has much higher cost than Grade 5 springs.

1. Its raw material cost is higher than Grade 5 titanium raw material

2. Spring wire production cost is much higher than Grade 5

3. The rates of finished products is lower than Grade 5 springs.Because when coiling Beta-C spring wire,it get broken easily and its finish will leave cracks after coiling.

4. Heat Treatment of Beta-C spring cost is high.

Super Grade 5 Titanium Springs

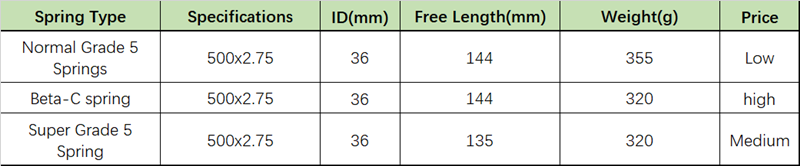

Recently,we researched an super titanium Grade 5 spring.This spring is still made from normal titanium alloy Grade 5 material,but designed with smaller spring wire diameter and less coils,it can reduce more weight than normal Grade 5 titanium springs.Though weight is reduced,but it still hold up the excellent features of titanium springs.It is proved by longer time riding. Just because the cost of “special treatment” is much higher than normal Grade 5 springs,so it has some higher prices than Grade 5 springs.But its price is still much lower than Beta-C titanium springs.Below is an example of comparison of different titanium springs.

From this example,we can see that the super Grade 5 titanium spring has the same weight as beta-C titanium springs,both of them has much lower weight than normal Grade 5 springs.Anyway,it is just an example,it is not means all super Grade 5 titanium springs has even the same weight as Beta-C springs.So before choosing a shock spring,you can consider much including spring weights,colors,and prices at first and then choose the fittest spring for your bikes.

Baoji HOSN Titanium Co., Ltd. is a company specialized with titanium springs design and production.We supply custom services for the titanium springs,and our MOQ is 1 piece.So just contact us if you want titanium spring for your bike.

Website: www.hosnti.com

Email: [email protected]